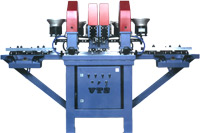

Type 150-2/ 50.4 has been developed to set small and beyond quadratic semi-tubular rivets – that means head diameter is bigger than length of the pole - fast and reliable.

Consequently built as single modules VTS Machines can easily be integrated as components within customized assembly lines.

VTS Riveting Machines contain a direct and centrical drive concept. This advantage allows a pneumatic-hydraulic impact element. Usually occurring losses of power as a result of impact redirection using flywheel, crank and con-rod e.g., simply do not appear in this concept.

It enables a nearly maintenance-free machine with only one point of lubrication.

It enables a nearly maintenance-free machine with only one point of lubrication.

Technical data:

- Stroke: 50mm

- Power stroke: 4mm

- Throat depth: 150mm

- Length of rivets: 15mm

- Diameter of rivets: max. 4mm

- Drive mechanism pneumatic/hydraulic

- Pressure: 8 kN at 4bar linear increasing (20kN at 10 bar)

- Air consumption 0,5l per lift at 4 bar

- Length of cycle: 1 second

- Rivet feeding: automatically via vibration bowl feeder

- Safety: automatic finger protection system

- Working height: 900mm

- Dimensions: 0,5m x 0,5m x 1,5m

- Weight: 120kg